Handling and Use

IQ Brick flat panels come in 16” x 24” sheets and adhere to your wall with 6 screws and finish with tuck pointing. IQ Brick can be cut and installed using with a diamond blade saw and shimmed to fit. When being cut to size, avoid breathing dust and minimize contact with eyes. IQ Brick should be stored off the ground in original shipment condition until ready for installation.

Product Limitations

Although IQ Brick has an integrated drainage plane, below-grade applications require a drainage board to be installed behind the panel. Manufacturer’s thin brick to be included within the IQ Brick panel should be either TBX or PCI. Typical IQ Brick clay thin brick sizes are Modular. Other sizes available by special request.

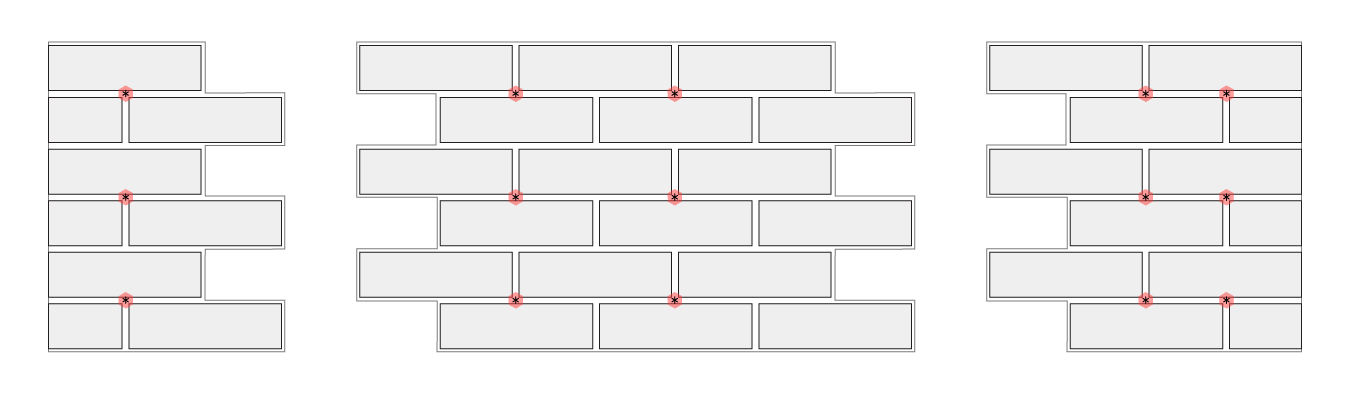

IQ Brick Standard Fastening Pattern

Scale: NTS | Revision: 01

Notes:

- Recommended fastener location at least one-half brick into the panel

- Do not use impact drivers

- Use 2,500 RPM max variable speed screw drivers with torque control or a depth sensing nosepiece

- If the IQ Brick panel is cut to one full brick or less (8” or less) at the most narrow part only (3) screws are necessary, alternatively a panel 8” or greater requires (6)

Learn More

Interested in learning more about the textures and finishes available with the IQ Brick system? Our team can provide samples, technical details, and guidance to help with your next project.